Nearly five years ago, the US Government issued rules that required automakers achieve a fleet average of 54.5mpg (23.17 kilometers per liter) for new cars and trucks—nearly doubling the average fuel economy. While eVehicles and hybrid technology switched development into the fast lane, the development of so-called “micro hybrid” and “mild hybrid systems” based on 48V power also shifted into high gear. As a result, the long-used 12V automobile electrical system is reaching the end of the road. 48V technology offers several advantages for both vehicle manufacturers and drivers. Not only does it reduce environmental impact, but it improves engine performance and, most importantly, fuel consumption. However, with new technologies, the sheer volume of electrical loads in vehicles is exponentially rising. Technologies including telematics, auxiliary electrical heating systems, complex drivetrain management, anti-lock braking systems (ABS), Electronic Stability Program (ESP), and dozens of others consume high levels of energy further complicating the design. While today’s alternators provide the power levels to keep up with this demand, a powerful buck-boost converter serves as the central component for 48V systems. In 1955, automakers introduced 12V charging systems, replacing older systems based on 6V technology. Between 1955 and the 1980s, standard alternator output typically fell below 0.5kW, although some high-efficiency alternators could produce as much as 0.7kW. Today’s vehicles require an alternator output of 3.5kW—seven times more output. A 14V alternator generates a 250A current, resulting in a maximum efficiency of only 70 percent. As a result, the engine must supply an additional 5kW. To compensate for this, large conductor cross-sections are required to supply higher currents, which add to the cost and weight of the vehicle. This weight decreases fuel efficiency and, subsequently, CO2 emissions increase.

48V Systems

Enter 48V technology. 48V technology allows the implementation of a number of features that are not practical in 12V systems, including the support of micro-hybrid and mild-hybrid systems. These features reduce both CO2 emissions and overall fuel consumption and include:

- High-performance energy recuperation at >5kW

- Extended start-stop functions, such as sailing or coasting

- Electrification of units such as turbocharger and electric power steering

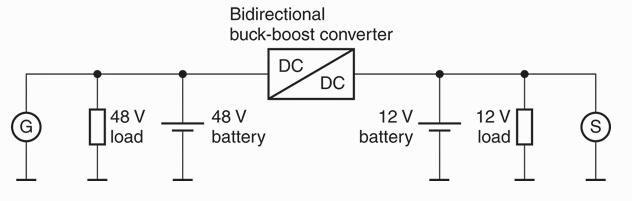

The 48V system is more of an extension than a replacement of the existing 12V architecture, which enables the system to handle more powerful loads through the use of a bi-directional buck-boost converter that controls both a 12V level and the 48V level (Figure 1). Think of this as version 2.5.

Figure 1: Architecture of a combined 12V /48V on-board power supply. (Source: TDK)

In this version 2.5, a standard lead-based battery is used for the 12V level, and a lithium-ion battery is used for the 48V level, where the generator is set, helping the realization of higher and more efficient output levels. New best practices specify connecting the double-layer capacitors in parallel for improved electrical storage.

Buck-boost Converter

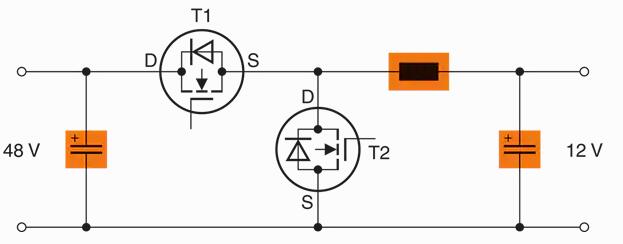

As previously mentioned, the central component of the combined 12V/48V system is the buck-boost converter, which controls the bi-directional energy flow between the two voltage levels (Figure 2). Most buck-boost converters are designed for outputs of between 2kW and 5kW.

Figure 2: Buck-boost converter circuit diagram for the combined 12V/48V system. (Source: TDK)

The buck-boost converter operates as a buck converter while in normal mode so that the power generated on the 48V level is outputted properly to the 12V system. If output is required at the 48V level, the boost mode will be used. Serially connected systems with 6 or 8 phases are typically used to keep voltage and ripple current to a minimum.

In order for the buck-boost converter to operate properly in harsh automotive environments, designers must use high-quality, reliable switching transistors, power inductors, and storage capacitors. For example, if the design calls for power inductors for the storage and smoothing chokes in the converters, ceramic SMD components should be specified. The power chokes should feature a third soldering pad in addition to the two solder pads for the winding to increase the mechanical stability of the components on the PCB. If an SMD inductor is not possible, inductors with PTH terminations can also be used. All components should be designed to operate in temperatures ranging from -40°C to 150°C.

Vibration-resistant Capacitors

Apart from the inductors, other key components in buck-boost converters should be robust aluminum electrolytic capacitors for storage and smoothing chokes in the converters. Such capacitors should also operate in temperatures of up to 150°C.

These capacitors should be specifically designed for the stringent demands of automotive electronics, like the B41689 and B41789 series from TDK. These aluminum electrolytic capacitors are characterized by their extremely high vibration strength of up to 60g and a soldering star design. Some capacitors come with cathode plate contacts on both ends to enable optimized mounting with low ESL values.

Specified capacitors should also feature low equivalent series resistance (ESR) values, which result in a higher ripple current capability and lower losses. The capacitors should be rated at voltages of 25V, 40V (for 12V), and 63V (for 48V). With these voltages, they can be used in the new on-board power systems at both voltage levels. The capacitance range extends from 360µF to 4500µF.

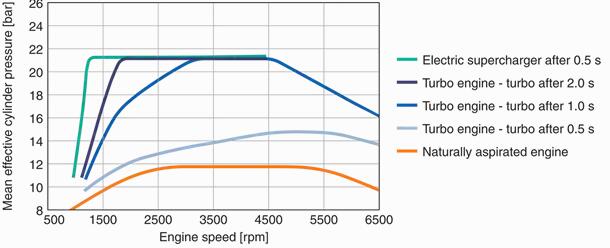

Electric Turbochargers

The 48V technology offers the added benefit of enabling electric turbochargers or e-turbochargers to drive engines more efficiently (Figure 3). Until recently, conventional turbochargers were driven by exhaust gases, which meant that they performed better as engine speed increased. One drawback of conventional turbochargers is the slight delay from the time when they are actuated until they kick on. This delay is known as turbo lag.

A 48V system removes this deficiency by using an electrically operated charger. This allows the turbocharger to respond instantly and also work at lower speeds, increasing overall efficiency, whether in urban traffic conditions or on the highway

Figure 3: Electric turbochargers increase engine efficiency. (Source: TDK)

In fact, combining a conventional turbocharger with an electric turbocharger further increases charging pressure so that the electrical charger can be switched off at high engine speeds, saving power and improving overall efficiency.

Not only does 48V technology improve engine performance and efficiency, but it is attractive to drivers who want to reduce fuel consumption. It creates a truly well-equipped automobile that can go from 0 to 60 (0mph to 60mph or 0kmph to 96.56kmph) in 48V. With all of the benefits this technology offers, it is no wonder that 48V electrical systems have shifted into high gear.